The aircraft engine industry is currently facing a myriad of challenges that are causing a bottleneck in engine repairs and overhauls. With parts and labor shortages, delayed deliveries of new airplanes from Boeing and Airbus, an engine recall, and premature repairs, aircraft engine shops around the world are struggling to keep up with the overwhelming demand.

Before the pandemic, the repair and overhaul of engines was a $31 billion business, but it has now swelled to $58 billion this year, according to Alton Aviation Consultancy. This surge in demand has created a cash cow for engine makers like GE Aerospace and other smaller specialists that service engines made by Pratt & Whitney and Rolls-Royce.

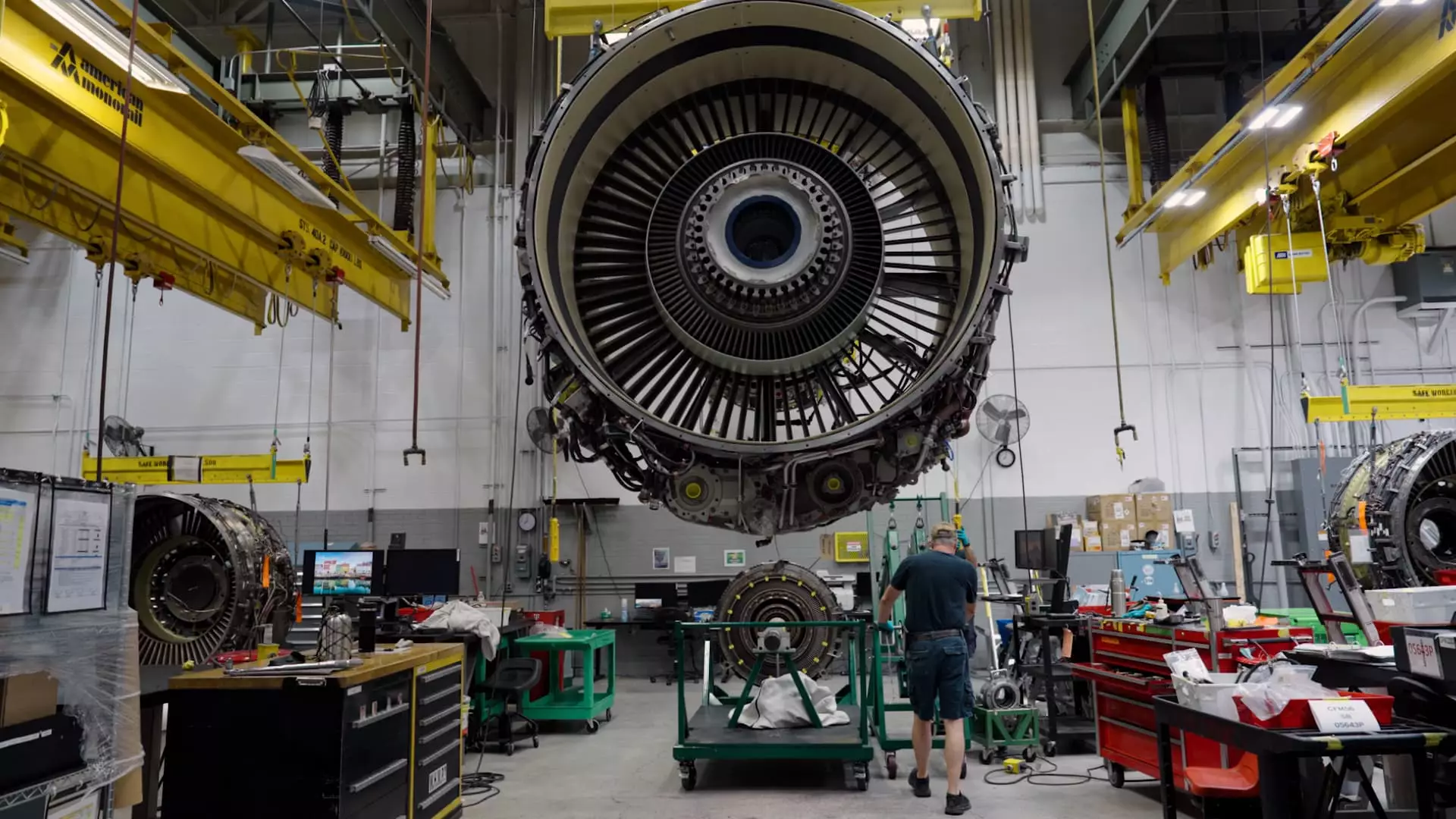

To address the challenges in the industry, American Airlines has taken matters into its own hands by increasing the amount of work it does in-house. By focusing on overhauling CFM56 engines, made by a joint venture of GE and Safran, American Airlines has significantly increased its overhauls. The airline’s bustling engine shop at Tulsa International Airport is on track to process more than 16 engines a month this year, up from five a month in 2022.

By controlling its own destiny in engine repairs, American Airlines has been able to reduce overhaul times significantly, completing them in less than 60 days compared to outside shops that take 120 to 200 days. This has allowed the airline to maintain its fleet more efficiently and effectively.

The bottleneck in engine repairs can be largely attributed to the industry’s rocky emergence from the pandemic. Companies shed thousands of skilled workers during the travel slump, and airlines that delayed maintenance then faced shortages and shortfalls of key items when demand snapped back.

In addition, delayed deliveries of new airplanes from Airbus and Boeing have forced carriers to hold onto older jetliners longer than planned, resulting in increased demand for maintenance and overhauls. The increase in routine maintenance for older airplanes has added to the strain on engine shops, with overhauls costing millions of dollars and requiring flawless key parts that are both hard to find and expensive.

With the ongoing challenges in the industry, many low-cost airlines, including JetBlue Airways and Spirit Airlines, are deferring new jet deliveries to save money. This has led to a significant impact on the engine supply chain, resulting in high demand for engine overhauls.

Engine suppliers like GE Aerospace have seen a surge in revenue from engine maintenance, repairs, and overhauls. For example, GE Aerospace generated $11.7 billion from engine maintenance in the first half of 2024, making up 65% of its revenue. The aftermarket engine business has become a lucrative opportunity for engine suppliers, with billions of dollars at stake.

Looking ahead, the aircraft engine industry faces both challenges and opportunities. As airlines continue to deal with the aftermath of the pandemic and the supply chain issues plaguing the industry, there will be a growing need for efficient and cost-effective solutions to engine repairs and overhauls.

With investments being made in upgrading engine shops and the rise in demand for replacement engines, there is potential for innovation and growth in the industry. As airlines adapt to the changing landscape of the aviation industry, there will be a greater emphasis on streamlining processes, reducing costs, and improving efficiency in engine maintenance and repairs.

The challenges facing the aircraft engine industry are significant, but they also present opportunities for growth and innovation. By addressing the current bottlenecks in engine repairs and overhauls, the industry can pave the way for a more efficient and sustainable future.